Advantages of Using a Coreless Slitter & Rewinding Machine for Tape

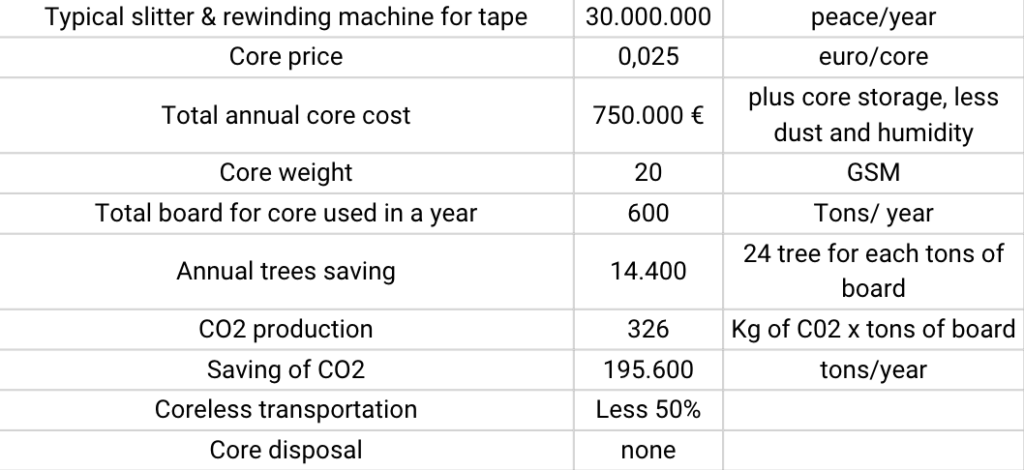

Adopting a typical coreless slitter & rewinding machine for tape offers numerous economic and environmental benefits.

Cost Reduction

Currently, the cost of a single core is €0.025, and the annual investment for purchasing cores amounts to €750,000. In addition to the direct cost, there are additional expenses for core storage, as well as issues related to dust and humidity. By eliminating the use of cores, a significant economic saving is achieved.

Lower Environmental Impact

Using cores results in the consumption of approximately 600 tons of board per year, with a weight of 20 GSM per unit. This has a significant environmental impact, as each ton of board requires the felling of around 24 trees. By switching to a coreless solution, it is possible to save up to 14,400 trees every year.

CO₂ emissions are also drastically reduced: the current production generates 326 kg of CO₂ per ton of board, leading to a total savings of 195,600 tons of CO₂ per year.

Logistical and Operational Benefits

Logistics significantly improve thanks to a 50% reduction in transportation volume, leading to lower greenhouse gas emissions. Additionally, since cores no longer need to be disposed of, the issue of waste disposal is eliminated, further enhancing the sustainability of the entire production process.

Conclusion

Investing in a coreless slitter & rewinding machine for tape is a strategic choice, not only from an economic perspective but also from an environmental one. Cost savings, reduced CO₂ emissions, and less deforestation make this solution highly sustainable and beneficial for the future of the industry.